Three important ways that they’re superior.

Gear-obsessed editors choose every product we review. We may earn commission if you buy from a link. Why Trust Us? Terminal Block

Replacing a broken taillight on my trailer reminded me of just how much I like solder seal butt connectors. Before I starting using them, I was always leery of using traditional crimp connectors, especially underneath a vehicle, exposed to the elements. My preferred wiring repair method was soldering, followed by covering with heat shrink tubing. That worked fine, but wasn’t always easy in confined spaces, or while working overhead. Plus, it often felt like you needed three hands to hold both wires just right, while also holding the soldering iron. And, then you had to hit it with a heat gun to shrink the tubing, and cover up the bare wires.

Earlier this year, I installed a flatbed body on my truck, with all new lights. This meant I had to splice wires for the new lights into the factory wire harness. I decided to try solder seal butt connectors to tie into the factory wires, mainly because they claimed to be waterproof. But I soon found there are more reasons to use them instead of traditional crimp connectors or soldering.

Compared to soldering, solder seal connectors simplify the repair by eliminating steps. You don’t need to tin both wire ends, you don’t need to hold them still while soldering them together, and you don’t need to use a soldering iron. You just use a heat gun, which you’d use anyway for the heat shrink tubing.

Compared to crimp connectors, solder seal connectors are watertight, create a much stronger connection that can’t be pulled apart, and are far less bulky. If you’ve ever had to patch into a harness, you know there is always a big lump created by the butt connectors. That lump can sometimes be a problem if you need to tuck the wiring back into a tight space.

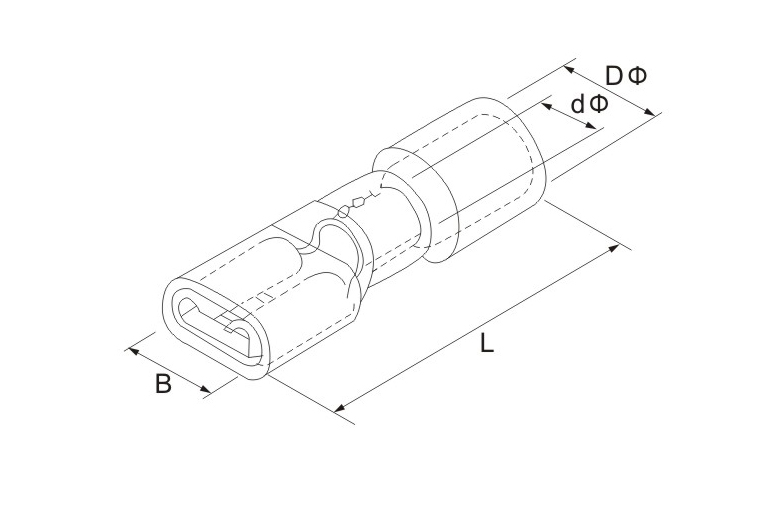

Solder seal butt connectors are made of a clear, heat shrink tube, with a low temperature solder ring in the middle. On either side of the solder ring, there is a colored ring of heat-activated adhesive. The colors of the heat activated adhesive help identify what size wires can be used with the connector.

The connector is slipped over one of the wires to be spliced together and then the stripped ends of each wire are pushed into each other. The connector is slid over the splice, with the bare wires both inside the solder ring. Heat is then applied to the tube via a heat gun, which first shrinks the tubing, then activates the adhesive, sealing the connector to the insulation around the wires, and finally melts the solder which flows into both wires.

Plus, consider that they’re easier to use than a soldering iron and require little to no practice or special skills. You will need a heat gun capable of reaching 750-1110 degrees F, but they’re relatively inexpensive—and if you deal with wiring regularly, the benefits of the connectors justify the cost.

Solder seal is a generic name for these connectors, and you’ll find there are many brands available. I have tried Solder seal connectors from both Kuject and Sopoby, which performed equally well. If you’ve ever wondered about these types of connectors, you should definitely try them—I don’t think I’ll ever use a crimper again.

Brad Ford has spent most of his life using tools to fix, build, or make things. Growing up he worked on a farm, where he learned to weld, repair, and paint equipment. From the farm he went to work at a classic car dealer, repairing and servicing Rolls Royces, Bentleys, and Jaguars. Today, when he's not testing tools or writing for Popular Mechanics, he's busy keeping up with the projects at his old farmhouse in eastern Pennsylvania.

How to Cure a Hangover, According to Science

America’s X-37B vs. China’s Shenlong Spaceplane

10 of the Hardest Math Problems Ever Solved

The Army Wants Explosive Reconnaissance Drones

Why Some Continents Go Missing

The Dark Truth About Cobalt Mining in the Congo

Solution to Riddle of the Week #12: Licking Frogs

Solution to Riddle of the Week #8

The 5 Most Notorious Moles in U.S. History

This Is the Coldest Place in the Universe

Do Sperm Defy the Laws of Physics?

A Part of Hearst Digital Media

We may earn commission from links on this page, but we only recommend products we back.

Crimp On Battery Terminals ©2024 Hearst Magazine Media, Inc. All Rights Reserved.