New StormStrong FRP technologies are engineered for key infrastructure projects that need to exceed standard resiliency specifications. #infrastructure #sustainability

StormStrong waterfront sheet piles at Cross Bay Veterans Memorial Bridge. Photo Credit: Creative Composites Group Corrugated Metal Roofing Sheet

Fiber-reinforced polymer (FRP) composites manufacturer Creative Composites Group (CCG, Alum Bank, Pa., U.S.) now offers the option to upgrade utility, waterfront, cooling tower and light pole products with StormStrong technology. This offering provides added resiliency for extreme weather conditions such as hurricane-force winds, blizzards and deep freezes.

Products available for the StormStrong upgrade include pultruded utility poles, utility crossarms, light poles, waterfront sheet piles, waterfront pipe piles and FRP cooling towers. According to the company, StormStrong products offer resiliency, durability and corrosion resistance for both grid and shoreline hardening and are a sustainable, environmentally friendly solution containing no chemicals or additives that can harm humans or the environment.

Having StormStrong infrastructure that can withstand damaging storm-related weather events and the increasing impacts of climate change, such as rising sea levels and more extreme weather, saves companies both time and money annually, CCG contends. Additionally, they offer installation efficiencies through the use of lightweight material that is easily transported and enables transport across undeveloped land with limited road access where heavier materials prove challenging and at times, impossible.

The versatile polymer shows new strength (and other advantages) in pultrusion and core materials applications.

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

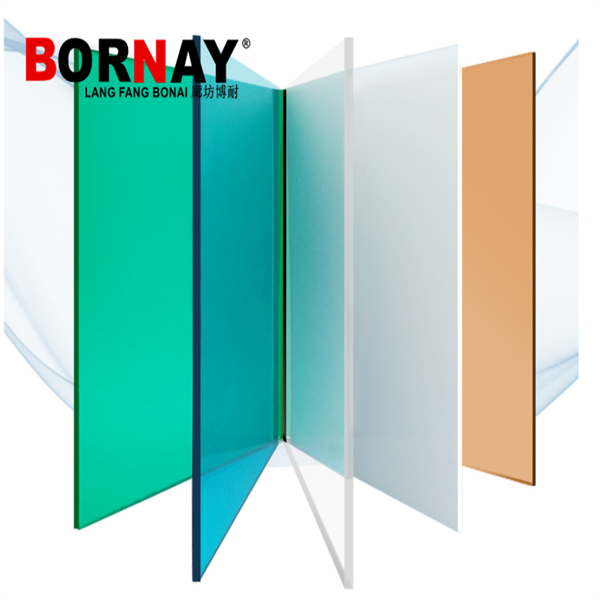

Polycarbonate Wall Panel © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]